The ultrafiltration process is a solution separation process based on the mechanical screening principle and the pressure difference between the two sides of the membrane as the driving force. Ultrafiltration is different from all conventional filtration and micropore filtration (all are static filtration). First, the ultrafiltration separation pore size is small, and it can intercept almost all bacteria, viruses and colloidal particles, proteins, macromolecules and organic matter in the solution. The other is that the whole filtration process is carried out under dynamic conditions, and only partial separation of the solution is obtained.

Index was outside the bounds of the array.

at Whir.Label.Dynamic.Location.GetLocationInfo() in E:\chenxz\05.ezEIP\ezEipV5.0\tags\V5.3.0(0649)\Whir.Label\Dynamic\Location.cs:line 317 at Whir.Label.Dynamic.Location.Render(HtmlTextWriter output) in E:\chenxz\05.ezEIP\ezEipV5.0\tags\V5.3.0(0649)\Whir.Label\Dynamic\Location.cs:line 103

Competitive advantage

Competitive advantage

Non-delamination: Using a proprietary membrane preparation process, the membrane separation material penetrates to the bottom of the entire support layer, so the membrane can be firmly embedded into the support tube to solve the separation problem between the separation layer and the support tube.

Friction resistance: A unique "peak and trough" filter inner surface structure supporting tube "peak" can protect the PVDF membrane located in the "valley" from the wear of high abrasive water, such as concentrated brine containing a large amount of mineral precipitation.

Super chemical resistance pH 1-13, filter material PVDF.

Microporous membrane, filtration accuracy: 0.2um, 50nm, providing excellent filtration water quality (generally less than 0.5NTU).

Large channel, cross-flow circulation, allows high solids load without pretreatment.

Technical advantages

Technical advantages

-

Suitable for high turbidity wastewater treatment, high surface flow rate, strong anti-pollution ability;

-

The process is stable, the process is simple, the membrane tube strength is large, not easy to break the wire;

-

Small footprint, compact structure, high degree of automation control, less operator configuration;

-

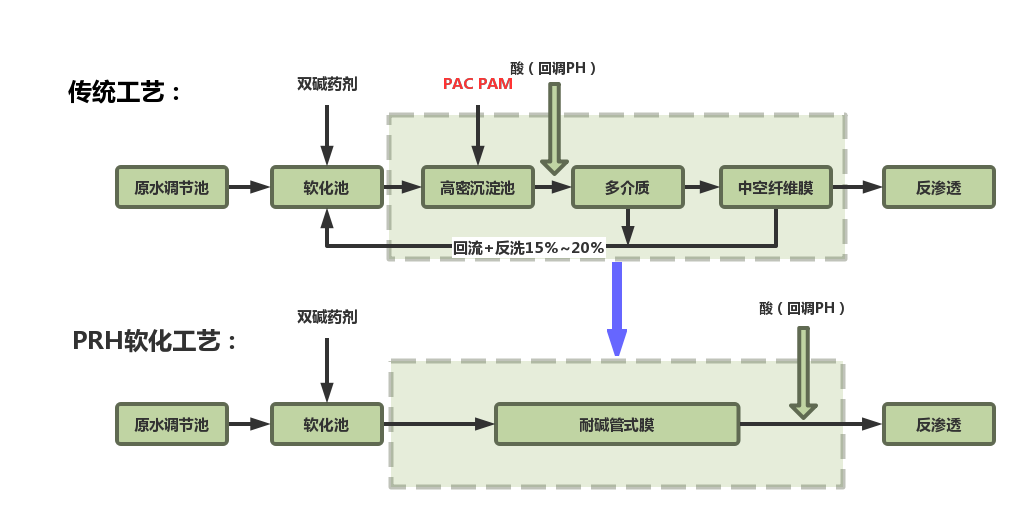

No need to add PAC, PAM and other coagulants, flocculants, to avoid the subsequent system caused by organic blockage, reduce environmental pollution, agent consumption, low cost;

-

Simple cleaning and maintenance, long service life, stable water quality, better than the traditional softening silicon removal method;

-

Good softening effect, the lowest total hardness of water production ≤50mg/l, calcium, magnesium ion ≤10mg/l.