Introduction to the technological process of hubei Zhongtephenol cyanide wastewater treatment station

Introduction to the technological process of hubei Zhongtephenol cyanide wastewater treatment station

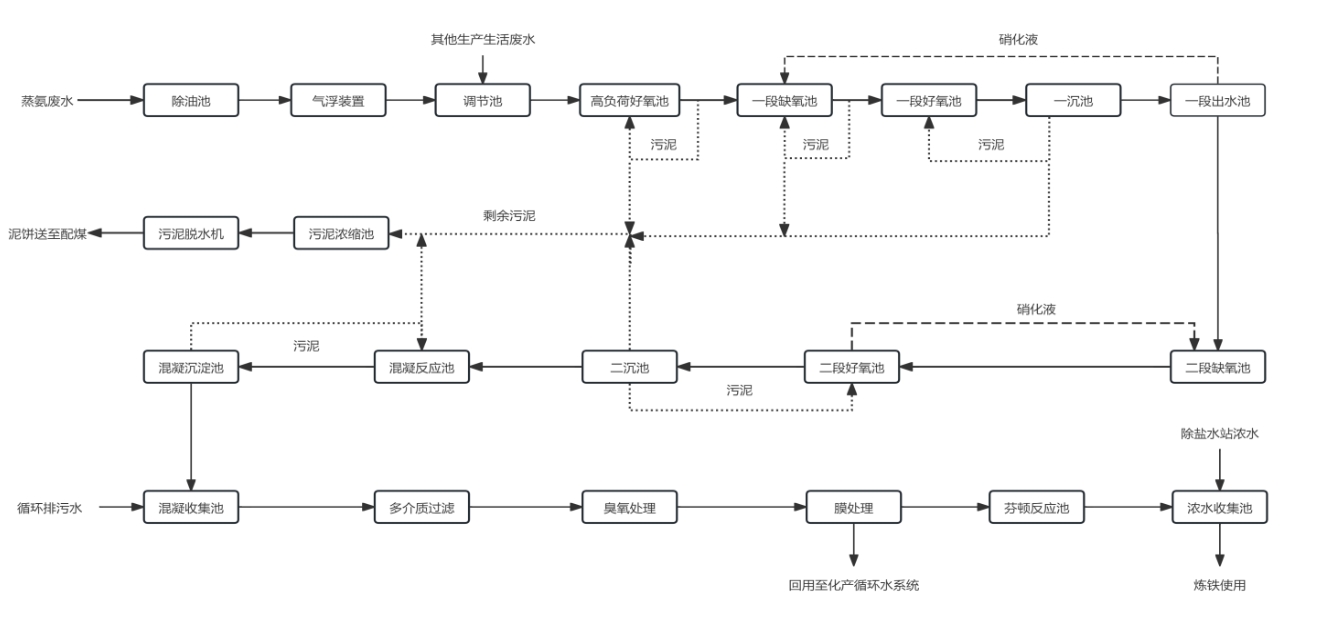

This phenol cyanide wastewater treatment station uses gravity deoiling and air floating deoiling methods to deoiling the system water to reduce the oil content of the water. After the homogenization of the regulating pool, it was promoted into the biochemical section. In the biochemical stage, the second-stage A/O biochemical treatment process is used to treat the cyanide containing wastewater. The wastewater enters the first-stage A/O to degrade and remove most of the polluting substances, and the effluent enters the first-stage A/O to separate the mud and water, and then enters the second-stage A/O treatment process for enhanced nitrogen removal to further remove the total nitrogen and organic matter that cannot be completely removed in the first stage A/O. The wastewater after biochemical treatment is separated by precipitation and then processed by physicochemical additive treatment. The water quality after treatment reaches the standard of direct discharge after adding coagulation agents and COD removal agents through precipitation separation and multi-media filter. The excess sludge of biochemical treatment and physicochemical treatment system is treated by sludge pressure filtration, and the sludge is used with coal. The chemical and chemical effluent and chemical production cycle effluent enter the ozone catalytic oxidation advanced treatment unit. Under the catalytic oxidation of ozone, the COD and chroma of the effluent are further reduced.

After ozone, the effluent enters the membrane treatment section after security filtration, the inlet water undergoes ultrafiltration and reverse osmosis treatment, and the membrane produced water is reused to the chemical production circulating water system. The concentrated water is sent to the Fenton reaction tank for treatment, and the water quality meets the requirements of GB16171-2012. The concentrated water is mixed with the concentrated brine of the desalination station and sent to iron making for use.